How Engine Components Optimize Excavator Fuel Efficiency and Reduce Operating Costs

In the construction industry, fuel efficiency is a key factor that directly impacts operating costs and environmental sustainability. Excavators, being heavy-duty machines, consume significant amounts of fuel during operations. The efficiency of their engine components plays a crucial role in optimizing fuel consumption. This article explores how engine components can enhance fuel efficiency and offers insights into reducing overall operating costs.

1. The Role of Engine Components in Fuel Efficiency

High-Precision Fuel Injection Systems

Modern fuel injection systems ensure precise delivery of fuel into the engine cylinder, optimizing combustion efficiency.

Advanced injectors reduce fuel wastage and improve power output, leading to better overall performance.

Turbochargers

Turbochargers compress the air entering the engine, increasing the amount of oxygen available for combustion.

This results in more efficient fuel usage and higher engine power without additional fuel consumption.

Piston and Cylinder Design

Lightweight and durable materials in pistons and cylinders reduce friction and energy loss.

Improved designs enhance combustion efficiency, maximizing the energy extracted from each drop of fuel.

Exhaust Gas Recirculation (EGR) Systems

EGR systems reduce nitrogen oxide emissions while maintaining combustion efficiency.

They help in achieving compliance with environmental regulations without compromising on fuel economy.

2. Practical Steps to Reduce Operating Costs

Regular Maintenance

Keep engine components in optimal condition through scheduled maintenance.

Replace worn-out parts like injectors, filters, and pistons to prevent fuel inefficiency caused by component degradation.

Use Genuine Spare Parts

High-quality, original engine components ensure compatibility and performance.

Genuine parts often come with better warranties and longer lifespans, reducing downtime and repair costs.

Adopt Modern Technologies

Incorporate advanced engine technologies such as variable valve timing and start-stop systems to minimize idle fuel consumption.

Monitor fuel efficiency metrics using telematics solutions to identify and rectify inefficiencies.

Operator Training

Educate equipment operators on best practices for fuel-efficient operation, such as avoiding excessive idling and maintaining optimal RPM.

Skilled operators can significantly reduce unnecessary fuel consumption.

3. Conclusion

Optimizing excavator fuel efficiency through high-performance engine components is a cost-effective strategy that benefits both the environment and operational budgets. Regular maintenance, the use of advanced technologies, and choosing reliable suppliers play a pivotal role in achieving these goals.

About Us

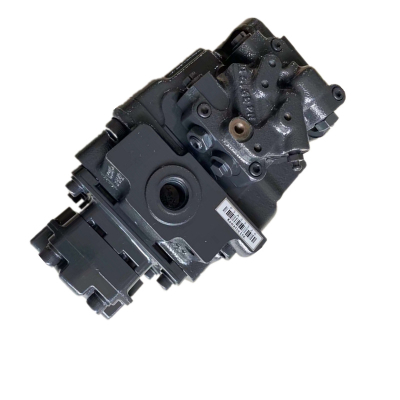

Our company specializes in providing premium engine components for excavators, including turbochargers, fuel injection systems, and pistons, designed to enhance fuel efficiency and durability. Our products are rigorously tested for quality and comply with international standards. Partner with us to reduce your operating costs and achieve higher productivity. For more information, visit our website or contact our expert team today.

This is our product page, please check→→Products

You can contact us here→→Contacts

See our article here→→News